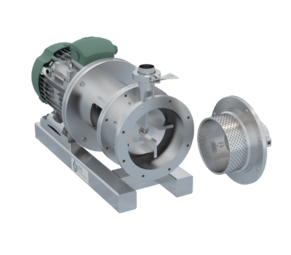

Inline High-Shear Mixer

The Inline High-Shear Mixer efficiently emulsifies, homogenizes, disperses, and reduces particle size in the pharmaceutical, food, beverage, and cosmetic industries This mixer provides mechanical and fluid power for manufactured products, producing results fast and reliable. It uses shear pressure and is ideal for applications that require uniform particle dispersion, immiscibility, and powder co-liquefaction.

The high rotational speed creates a strong drag force, which pulls the material into the mixing chamber, causing rapid, turbulent movement and fluidization

Special Features:

- Efficient mixing:Inline High-Shear Mixer rate ensures uniform mixing, reduces particle size and forms a stable emulsion or dispersion.

- Inline configuration: The mixer integrates directly into the production line, enabling continuity and eliminating the need for batch processing.

- Compact design: requires minimal space, making it ideal for tight spaces while maintaining energy efficiency.

- Versatility: It can handle a wide range of applications from low volume liquids to low volume chemicals.

- Easy Maintenance: Designed with simple assembly and disassembly for quick maintenance and repair.

Benefits:

- Consistency of product quality: Assures that the finished product has a consistent texture, particle size and consistency.

- Time and cost efficiencies: Inline manufacturing reduces production time and labor costs, increasing productivity.

- Improved process control: The adjustable rotor and stator arrangement precisely controls particle size and energy mixing.

- Scalability: Available in various sizes to fit pilot-scale or industrial-scale production