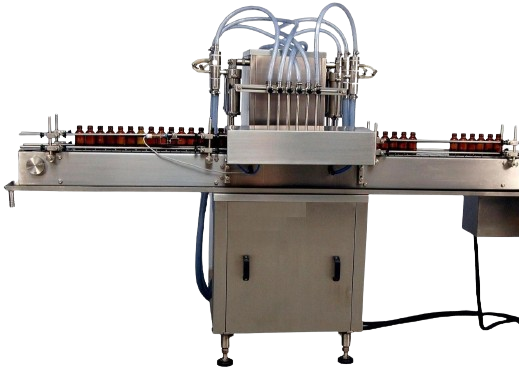

BOTTLE FILLING MACHINE

Bottle-filling machine play an important role in the food, beverage, cosmetics, and pharmaceutical industries, accurately filling bottles such as liquids, gels, creams and other products.

They have sophisticated technologies such as volumetric, gravimetric, or piston-based filling systems and are available in versions such as automatic, semi-automatic, manual models Features include multiple fill heads, anti-drip mechanisms, customizable fill speeds, easy clean designs to avoid contamination Bottle filling machines of precise, reliable , of the skilled f are important for industries requiring solution filling because they maximize productivity, save waste, and provide uniformity in batches

Our bottle filling machines provide convenient and fast filling solutions for the food, beverage, cosmetics, and pharmaceutical industries. These machines are precisely designed, using liquids, gels and creams with unparalleled accuracy, ensuring they are replenished every time

KEY FEATURE

Versatile Filling Types: Allows for a variety of viscosities with the aid of three filling types: piston-based, gravimetric, and volumetric.

Automatic efficiency: Automatic, semi-automatic, and manual options are available to accommodate various production scales.

Adjustable settings: Injection rate, speed and nozzle typeto meet the needs of specific applications.s.

Anti-Drip & Anti-Spill Design: Technologically advanced nozzles prevent spills and leaks, reduce waste and preserve cleanliness.

Easy Cleaning and Maintenance: Made from quality materials, this product is easy to clean and ensures compliance with industry requirements.

Types of Bottle Filling Machines

Gravity filling devices: These devices use gravity to transfer water from the tank to bottles, making them perfect for low-density, non-carbonated water (such as water, juice and oil) Widely used in the food and beverage industry, easy to use and affordable.

Piston Filling Machines: machines use a piston to measure and dispense exact amounts of solid liquids such as creams, gels, syrups, and sauces. This device is ideal for cold applications and provides excellent accuracy in packaging.

Filling Machines: Mechanical filters fill plain to simple liquids such as thin sauces, essential oils and spices. Following a technique dating back to the 19th century, it directs the flow of water in each container vacuum fillers are especially useful for fragile glass bottles and similar containers.

Overflow Filling Machines: Typically used for blended and soft juices, are ideal for products in the beverage, household and cosmetics industries that require consistent, sleepy filling of each bottle expressed, with even slightly different amounts

Mechanical Injection Pumps: Injection pumps are capable of controlling a variety of solids from thin liquids to heavy chemicals using a variety of pumps (gear, diaphragm and peristaltic)